Machining Monitoring

Machine Tool Productivity

Many factors in machining affect productivity of operations. The very first condition to measure actual productivity is to regularly collect information from machines and process them with correct methods.

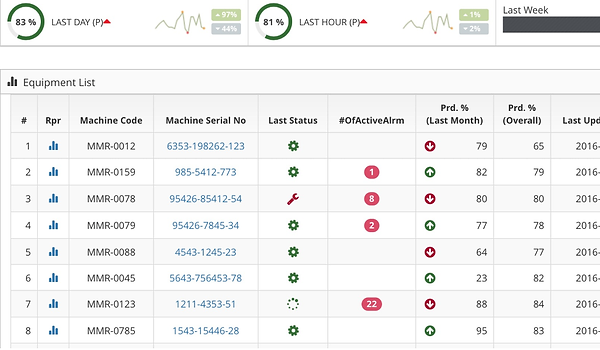

MachineTracker closely monitors start/stop/on-hold/offline events of machine tools to measure productivity as a function of time. In addition, areas where productivity suffers are effectively highlighted to help manufacturing engineers spot and remove obstacles in production. Critical human interventions to the process such as feed and spindle speed override events that help analyze why original cutting conditions are modified in the post-production analysis are also logged in great detail with time stamp, program line number, and percentage override.

Alarm Logging

Alarms are regularly encountered in machine shops due to many reasons, some of which are related to programming/operational mistakes whereas some indicate critical system errors. Each alarm event contains an alarm number and a detailed description in text. All alarms occuring in the day are logged and classified based on their severity. Statistics such mostly encountered alarms and most alarming machines are reported to the user.

Instantaneous Operation and Machining Information

User can connect to any machine in the system to follow instantaneous operation information together with machining parameters (feeds, speeds), current program name and its settings, active line number, axes positions, and spindle loading.

Spindle Condition Monitoring

Spindles are one of the most heavily used components on a machine tool and subjected to gradual wear, which may be long-term. Testing of spindles on a regular basis is critical to

-

Reduce the risk of severe failures, breakdowns and compromised part quality,

-

Minimize unexpected downtime due to equipment failure,

-

Ensure high consistency between the produced parts,

-

Take timely and planned actions for the risky spindle.

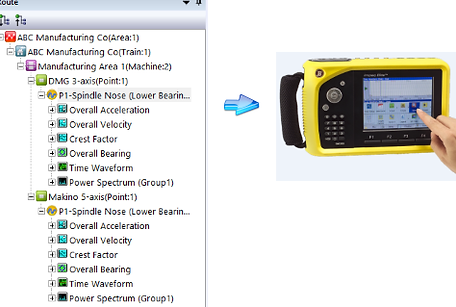

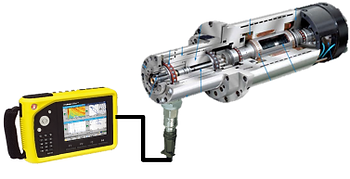

Required equipment for spindle condition monitoring is a hand-held vibration analyzer - ImpaqElite and industrial accelerometer.

First step is to identify all machines in the facility then create a route on ImpaqElite, which contains target machines selected for monitoring, and key parameters needed for equipment health evaluation. All critical settings are completed by experienced engineers.

Periodically, field engineer follows the route and easily collects data from all machines in the field. Measurement equipment settings are pre-defined hence field engineer is not required to make any adjustments.

Field data is automatically transferred to PC after connecting portable analyzer via USB cable. Through iSee software, all warning, alarms, and trends can be easily seen by the user. Historical field data is stored on local PC database.

Smart Equipment Protection

Machine Tool Collision Avoidance

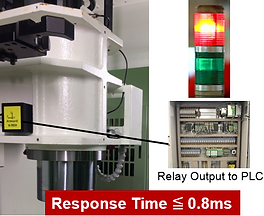

Mistakes are sometimes unavoidable in production and they can disturb your normal flow of production that will result in increased labor prices and delay customer delivery. They also result in overhead costs for repairing broken instrumentation and replacement of scrapped material. Operational errors, incorrect positioning of fixture and parts, programming mistakes etc put expensive equipment under tremendous risk and may result in sudden collision that cannot be prevented with human intervention. During collision, permanent damage occurs within a few seconds after the first encounter of objects. ArmourG closely monitors machine's physical state and immediately stops it under one sec, i.e., before permanent damage occurs.

Spindle Protector

Machine tool spindles contain high precision ball bearings. A major contributor to premature spindle failure is caused directly by the machining process. Excessive vibrations during machining may occur due to improper cutting conditions, fixture/part/tool flexibility, machine position (large head overhang), tool wear etc. Vibrations at cutting point are immediately transferred to bearings and precision balls start hitting against bearing tracks causing micro damages on their surface. ArmourSP continuously measures spindle vibrations and stops machining to protect spindle when excessive vibrations are encountered.

Thermal Monitoring

Heat generation during production is inevitable. Mechanical, structural, hydraulic and electrical components generate and/or absorb heat in the machining environment. Temperature of these components must remain below certain threshold for healthy operation. ThermoMax monitors up to 8 thermo-couple placed at critical locations of the machine tool, records them for future troubleshooting and puts machine to alarm state in the case of emergency.

High Performance Data Acquisition

General Purpose DAQ

In machining, measurement of physical properties requires more than just data acquisition. Signals from microphone, displacement sensor, accelerometer etc shall be correctly sampled, filtered, processed and then converted into meaningful quantities. VimoNet sends digital data directly to the client simplifying development, maintenance and support. It does not require bulky driver installation on the client side; therefore, keeping computation load very light and simple. VimoNet also has relays to send commands to devices for alarms.